Springs are an integral component in virtually all industries, and while there are multiple types of springs, steel springs are among the most popular options. If you want to learn more about steel springs, this post has outlined the four types and their applications.

What Makes Up a Steel Spring?

As aforementioned, steel springs are made from two different steel types, mainly carbon steel and stainless steel. Carbon steel (music wire steel) is a fantastic option for its quality and uniformity. Nonetheless, this steel type is prone to rust, hence the popularity of the other option—Stainless steel. Why? Stainless steel is rust-resistant and is commonly used in wet places.

Steel springs are formed from hardened wires, specifically strengthened to suit different applications. The process starts with heating a large metal bar to malleability. Afterward, this steel is usually drawn through several dies that steadily decrease in size to the desired spring diameter needed.

What Are the Four Types of Steel Springs?

Compression Steel Springs:

These are the commonest type of steel springs. Operating contradictory to the extension springs, steel compression springs have remarkable energy when compressed and remain at rest when extended completely.

Compression generates the mechanical energy necessary to carry loads. Therefore, these springs are built to absorb any force or hold weight through resistance.

Steel compression springs shrink when force is applied and expand when the force is removed, releasing the mechanical energy stored. Depending on their specific application, these types of springs are made in various shapes, sizes, and configurations—hourglass, conical, and even barrel.

Compression steel springs are commonly used in force generators, shock absorbers, and other components like vibration dampeners.

Extension Steel Springs:

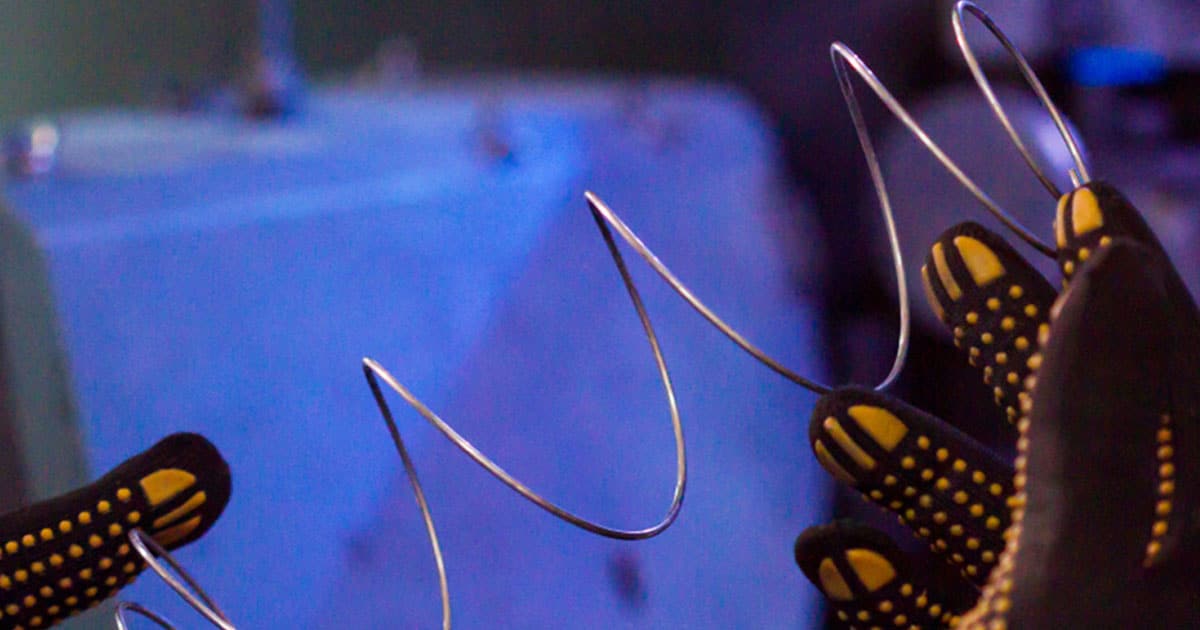

Also called tension springs, extension steel springs are designed to function through the concept of tension.

These steel springs are built with loops or hooks on either end attached to other components in a given mechanical assembly. These springs expand and resist their pulling force on pulling the components apart. After releasing this pulling force, the components retract to their initial position with the assembly.

Ideally, extension springs assume a rest state when tightly coiled and produce the most mechanical force when extended.

Constant Force Steel Springs:

As unique as their name sounds, they differ in function and design of the common helical-wound springs. Constant force springs exert a standard torque or force that remains constant across a massive motion range. Ideally, this makes constant-force steel springs valuable in applications that need some form of retraction or counterbalancing mechanism.

Constant force steel springs are made from a quality, high-yield thin stainless steel pre-tensioned spring wire that is expertly coiled into their flat spiral shape. When you uncoil the flattened strip, the energy is stored within this strip. Furthermore, its flat spiral shape allows for large angular deflection of many revolutions, although it only utilizes a small part of its entire extension capacity.

Torsion Steel Springs:

A torsion steel spring is a uniquely flat, spiral coil-shaped steel spring used to apply rotational or torque energy. These springs operate opposite to extension and compression springs that need a linear force for pulling or pushing since they use torque.

Torsion springs rotate on their axis when resisting or applying a load. The mechanical energy torsion springs offer is stored and released through twisting or rotational action. Based on this concept, these steel springs are common in applications needing torque or rotational force, like lever returns, counterbalances, and hinges. Generally, torsion steel springs are usually mounted at several points (three or more) to allow the mounting.

Some common uses of torsion steel springs are automobile doors, tailgates (found in trucks), or agricultural and heavy-duty industrial equipment.

For Quality Steel Springs and Accessories

Ultimately, these four most common steel springs are designed to accommodate different applications. Although numerous metal spring types are made for different uses, most are structured to serve the four functions of applying mechanical force—tensile, compressive, counterbalance, or torque.

Foshan Gonglian Metal Products Co., Ltd. (GL Metal)is your best bet for the best quality steel springs. The company is the best supplier for all your unique spring needs, with over two decades of production and industry experience and extensive custom stainless-steel production.